Logistics operations that run

on predictable execution

We design, build, and run execution-first logistics systems for transporters, 3PLs, and distribution networks – route planning, on-ground proof of delivery, and live control towers that keep fleets, branches, and customers aligned.

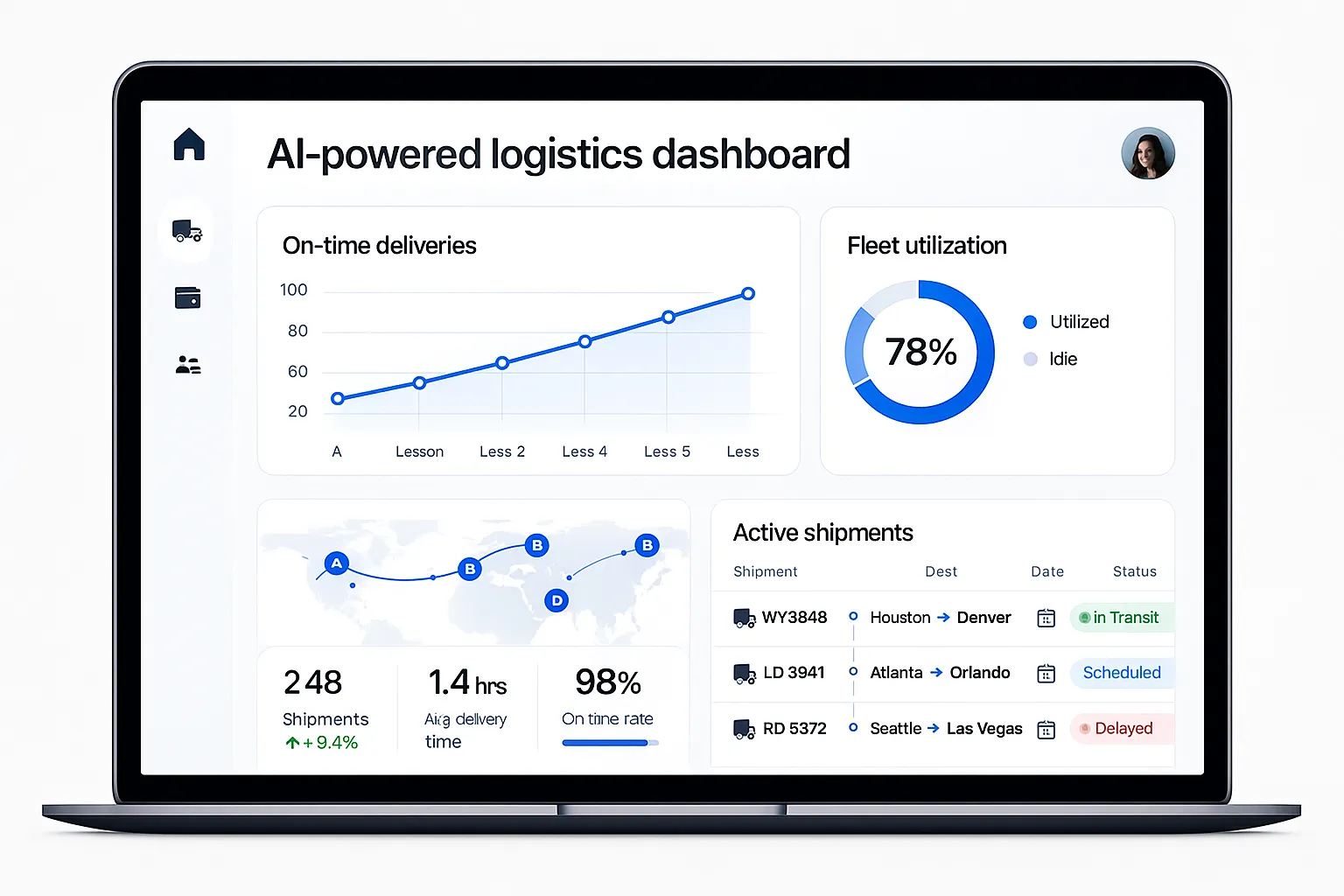

AI-driven logistics that turn fleets, lanes, and loads into predictable performance.

We design, build, and run logistics platforms that sit on top of your existing stack—optimising routes, utilisation, and service levels in real time across hubs and fleets, without disrupting your partners, drivers, or current systems.

Where logistics and transport operations leak efficiency.

Across fleets, hubs, and corridors, the patterns repeat: static route plans, manual coordination, and fragmented visibility. We focus on the leverage points that move OTIF, cost per trip, and asset utilisation.

Lanes, demand, and constraints shift daily, but planning stays locked in spreadsheets. Dispatch teams fight fires instead of orchestrating the whole network.

GPS feeds, WhatsApp updates, and TMS reports live in silos. Finance, operations, and customer teams rarely agree on where a shipment actually is.

PODs, gate passes, and exceptions move as paper or photos. There is no lightweight system that captures events at each touchpoint and feeds them back into planning.

A digital control layer across your logistics stack.

No rip-and-replace. We design an AI-first layer that plugs into your existing TMS, WMS, ERP, GPS providers, and on-ground workflows—so your teams and partners keep working as they do today, just with smarter infrastructure underneath.

Dynamic routing that balances cost, time, and constraints—vehicle type, capacity, driver hours, and SLAs—across lanes and service areas.

Clean event streams from GPS, apps, and partners that produce a single, trusted view of where every truck and shipment is, and what’s at risk.

Simple mobile flows for drivers, hub staff, and partners—trip allocation, checklists, POD capture, and exception logging tuned for low-friction use.

Tools that surface which lanes are profitable, which customers or corridors are breaching SLAs, and where to add or reduce capacity.

We integrate into your TMS, ERP, WMS, and GPS vendors so data contracts are clear, reconciled, and ready for analytics and automation.

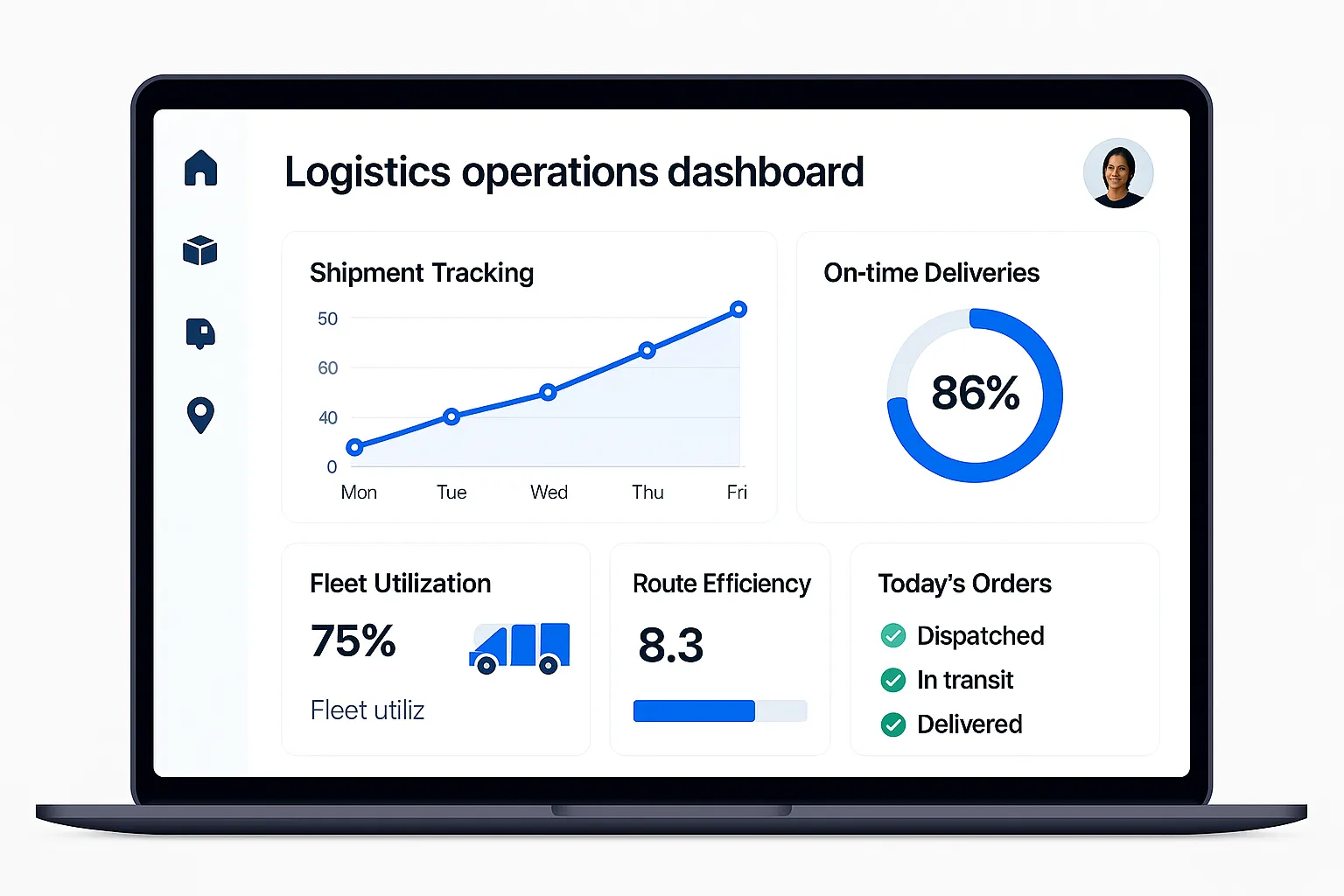

Live views of lanes, fleets, and exceptions with playbooks and alerts—so operations teams focus on interventions that actually move KPIs.

Want to see what a logistics control layer could do for your network?

Share your key corridors, fleet mix, daily shipment volume, and service-level targets. We’ll map 2–3 high-impact logistics plays you can implement over the next 8–10 weeks— with expected impact on cost per trip and OTIF.

Outcomes that matter to operations and finance.

Every deployment is anchored to hard metrics—cost per trip, OTIF, capacity utilisation, and exception rate—not just dashboards or “digital transformation” language.

Better routing, higher fill rates, and fewer empty miles across your fleet and partners.

Clear visibility, earlier risk flags, and structured escalation reduce missed SLAs and unhappy customers.

Fewer “Where is my truck?” calls, WhatsApp threads, and spreadsheet reconciliations for central and hub teams.

How we engage with logistics and transport teams.

A structured rollout that respects your lane rhythms, customer SLAs, and partner ecosystem— without putting day-to-day operations at risk.

- 01. Discovery & network mapping. We align with operations, finance, and customer teams to understand your network, lanes, contracts, and SLAs.

- 02. Architecture & pilot design. Together we choose where to start—one region, one corridor, a specific customer, or a fleet segment.

- 03. Implementation & guardrails. We deploy the logistics layer behind your existing systems, with clear control surfaces for dispatch and hub teams.

- 04. Scale-up & continuous optimisation. Once impact is proven, we extend coverage to more lanes, partners, and use-cases.

Frequently Asked Questions

-

What are the advantages of using Whizzystack for logistics and transport? ▾

You get a custom logistics layer that respects how your operations, finance, and customer teams already work. Instead of a black-box product, we build transparent systems that plug into your stack and governance.

-

What collaboration types do you offer? ▾

Most clients work with us as a project build with a clear scope, a retained logistics squad that co-owns the roadmap, or an advisory layer on top of internal engineering and operations teams.

-

What is Whizzystack’s unique logistics proposition? ▾

We sit at the intersection of logistics operations, engineering, and data. That means the systems we build are technically sound, measurable, and tuned to how fleets and hubs are actually run day-to-day.

-

Why should I introduce AI into my logistics and transport operations? ▾

AI allows you to respond to changing demand, traffic, and constraints faster than manual teams—adjusting routes, loads, and priorities continuously while people focus on customers and exceptions.

-

How does Whizzystack ensure compliance with contracts and regulations? ▾

We design with your legal and compliance teams from the start: data contracts, access controls, logging, and approval flows are part of the architecture, not an afterthought—especially around SLAs and regional rules.

-

You may be more expensive than generic development vendors. Why choose you? ▾

Our work is measured against cost per trip, OTIF, and asset utilisation— not just delivered features. The goal is for the logistics layer to pay for itself through performance gains within a defined window.

-

How do you handle data privacy and ethical use of AI in logistics? ▾

We minimise sensitive data, respect regional regulations, and avoid opaque automated decisions on critical business levers without human visibility and override options.